By Emily Li Lead Display Quality Engineer at RisingStar

About the Author

Emily Li brings over 8 years of experience in display manufacturing, defect analysis, and quality control. At RisingStar, she leads mura detection and calibration projects, utilizing both human expertise and automated imaging systems to ensure the integrity of industrial-grade LCD panels.

Introduction

In the display industry, the term "Mura" (a Japanese word meaning "unevenness" or "blemish") refers to non-uniformity in brightness, color, or texture across a panel. These defects manifest as patches, streaks, or "clouding" that degrade the visual experience.

For an LCD manufacturer, shipping a display with a mura problem is a disaster. It is particularly critical for high-reliability applications, such as outdoor digital signage and industrial high-brightness monitors , where consistency is paramount.

What Causes the Mura Effect?

Mura is rarely the result of a single factor. It generally stems from subtle imperfections during the manufacturing process or physical stress:

Layer Inconsistency: Variations in the thickness or density of liquid crystal layers.

Backlight Non-uniformity: Inconsistencies in LEDs or light diffuser plates.

Material Impurities: Contaminants or particles trapped within the panel layers.

Mechanical Stress: Thermal expansion or physical pressure during the assembly of the panel into its housing.

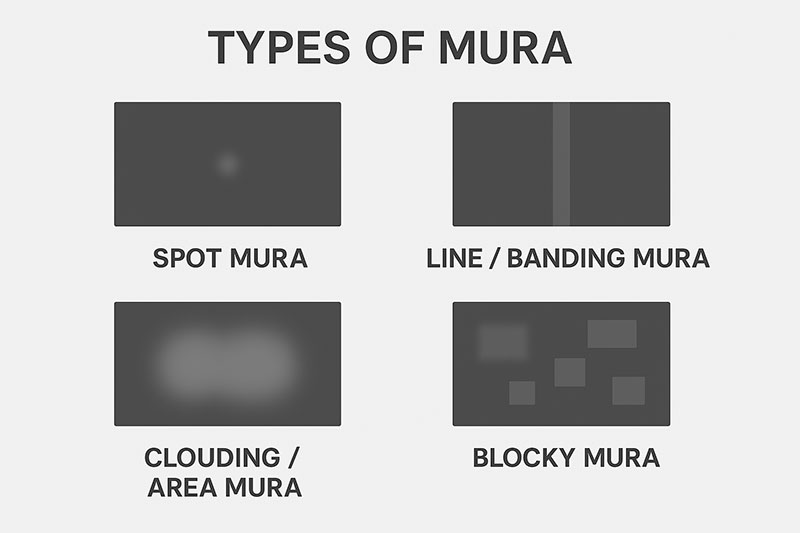

Common Types of Mura Problems

Understanding the visual signature of mura helps in identifying the root cause in the production line:

Type | Appearance | Common Cause |

Clouding (Area Mura) | Large, diffuse patches of uneven brightness. | Backlight inconsistencies or improper light diffusion. |

Banding / Line Mura | Horizontal or vertical streaks across the screen. | Non-uniform pixel response or driving voltage variations. |

Spot Mura | Small, localized bright or dark irregularities. | Impurities in liquid crystal or localized pressure points. |

Mura Noise | Random, grainy fluctuations in color or brightness. | Misalignment of liquid crystal molecules. |

Real-World Testing: The RisingStar Protocol

At RisingStar, we perform a rigorous multi-stage testing process on panels sourced from Tier-1 OEMs like LG, BOE, and AUO. We test upon arrival (Open-Cell) and again after the 72-hour aging test post-assembly.

1. Visual Inspection

Trained engineers examine the display in a dark room. While subjective, this is the most intuitive method for catching obvious defects.

2. Gray-Level & Luminance Analysis

We display specific gray-level patterns to measure luminance across different zones. Any deviation in "nits" beyond a specific tolerance indicates a mura defect.

3. Image Subtraction & JND Mapping

Using tools from Radiant Vision Systems, we use imaging colorimeters to create Just Noticeable Difference (JND) maps. This objectively quantifies defects that the human eye might miss but a customer might notice.

4. Machine Learning Detection

We are increasingly deploying CNN (Convolutional Neural Networks) to automate detection. These algorithms can classify mura types with over 90% accuracy, ensuring objective quality control.

Solutions and Mitigation Strategies

To ensure only A+ Grade panels reach our customers, we employ the following strategies:

Manufacturing Optimization: Refining liquid crystal alignment and improving the precision of backlight assembly.

Compensation Algorithms: Developing software that dynamically adjusts the output of specific pixels to "mask" or balance out non-uniformity.

Uniformity Enhancement Films: Applying specialized optical films that help diffuse light more evenly across the surface.

Calibration: Fine-tuning brightness, contrast, and gamma settings during the final assembly stage to compensate for panel-specific inconsistencies.

Conclusion

Mura is a complex challenge, but it is not insurmountable. By blending rigorous testing, expert human analysis, and emerging AI technologies, manufacturers can ensure high-quality display performance. At RisingStar , our commitment to double-testing and 72-hour aging ensures that every screen meets the demanding standards of industrial and outdoor applications.

#Luminance uniformity #JND (Just Noticeable Difference) # Backlight bleeding , A+ grade LCD panel

Last Updated: August 11, 2025

For technical inquiries or custom mura testing solutions, please contact quality@risinglcd.com or leave a comment below.

Disclaimer: All testing data reflect in-factory conditions. Actual results may vary based on environmental factors and specific usage scenarios.

English

English Deutsch

Deutsch Français

Français Español

Español Italiano

Italiano 한국어

한국어 日本语

日本语 Português

Português Suomi

Suomi Dansk

Dansk Polski

Polski