Self-service ticketing and vending kiosks deployed outdoors or in semi-outdoor transit gateways require displays engineered for direct sunlight, wide temperature ranges, moisture, impact and long unattended runtime. Modern solutions combine high-brightness LED backlights (1,000–5,000 nits), optical bonding and anti-reflective treatments, rugged IP/IK enclosures, and railway/traffic-grade certifications (where applicable). Europe’s digital signage and kiosk market is growing fast; distributors who offer technically validated, standards-compliant high-brightness displays for ticket machines can win long-term contracts with transit authorities, parking operators, and mobility service providers. Market reports estimate Europe’s digital signage market at roughly USD 7.98 billion (2024) and project strong CAGR through the 2020s — signaling steady demand for outdoor display solutions.

Self-service ticket kiosks and vending machines are now critical touchpoints in transit networks (rail, tram, metro), municipal parking, EV charging hubs, and event access points. For user acceptance and transaction throughput, the display must be readable at a glance even in high ambient light; it must also remain reliable across seasons, resist vandalism and weather, and deliver many years of maintenance-free operation. Typical functional requirements:

Legible UI and fare details under direct sunlight and reflections.

Reliable touch performance (if interactive) with gloved fingers or stylus.

Low failure rate and long MTBF for unattended operation.

Conformance to local safety / vehicle / infrastructure standards when installed on platforms or at roadside.

Conventional indoor LCDs are optimized for dimmer indoor environments (200–500 nits). Outdoors, direct sunlight can easily exceed 50,000 lux and completely wash out low-brightness displays. The engineering tradeoffs to overcome this are:

Increase peak luminance (nits) of the backlight — modern “sunlight readable” displays commonly start at ~1,000 nits and extend to 3,000–5,000 nits for truly bright installations.

Improve perceived contrast via optical bonding and anti-reflective coatings to reduce surface reflections and internal air-gap reflections. Optical bonding can dramatically reduce perceived glare and improve contrast.

Use ambient light sensors and automatic dimming to balance visibility and lifetime/energy consumption.

Use high-contrast UI design (large fonts, bold icons, high color contrast) on top of hardware measures to optimize read-ability at distance.

Below are high-value verticals and scenarios where European distributors should prioritize offering high-brightness ticketing displays.

Use case: Ticket purchases at open platforms exposed to full daylight, sometimes snow, rain, or sea spray (coastal stations).

Requirements: EN50155 (when equipment is installed on rolling stock or integrated into vehicle subsystems), high ingress protection, shock & vibration tolerance for rail-side cabinets, broad operating temperature range. EN50155 is recognized in railway equipment procurement.

Use case: Semi-outdoor concourses with highly variable ambient light.

Requirements: 1,000–2,500 nits, optical bonding, anti-glare glass, quick response capacitive/PCAP touch that supports gloved users.

Use case: Kiosks located adjacent to busy streets or plazas subject to dust, rain, vandalism and temperature swing (Northern and Southern Europe extremes).

Requirements: IP65–IP66 enclosures for splash & dust protection; IK08–IK10 impact resistance; tamper-resistant mounting.

Use case: Payment and session control at outdoor parking lots and EV charge points. Visibility during bright summer sun is crucial for transaction speed.

Requirements: 1,000+ nits, robust power management for grid/solar installations, extended warranty options.

Use case: Tourist information kiosks, festival box offices where intermittent high footfall demands readable displays for queueless purchase.

Requirements: Aesthetics + ruggedness; modular sizes (15"–24" for kiosks; 32"–55" for larger wayfinding or advertising + ticket combo units).

Below are practical hardware build recommendations (display-centric) that map to the application scenarios above. For each configuration I list the minimum recommended specs and why they matter. (You can adapt brand/model names to preferred inventory.)

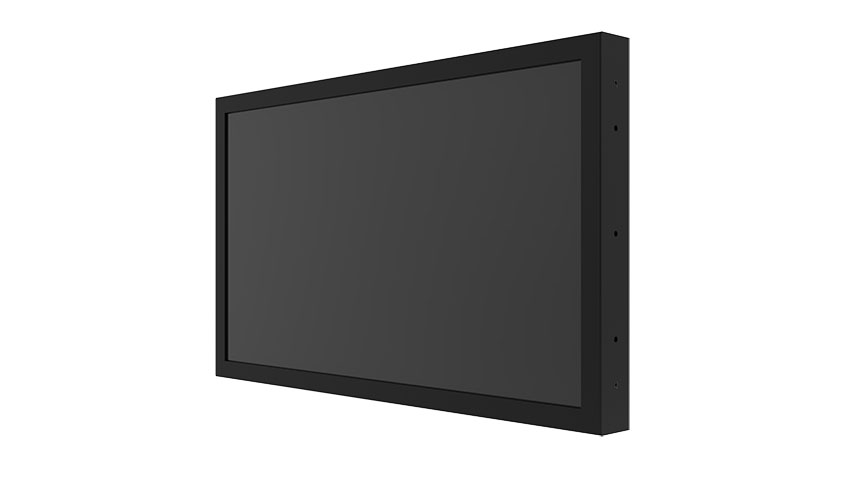

Display size: 10–15″ (touch)

Brightness: 1,200–2,000 nits (auto dimming with ambient sensor) — ensures legibility at head height and reduces power when idle.

Contrast: 1500:1+ with optical bonding

Surface: Tempered glass with AR coating + AG finish

Ingress: IP65 front face (recommended)

Touch: PCAP with glove mode or projected capacitive with anti-water filters

Typical models to consider: Industrial 12.1″–15″ high-brightness LCM modules with optical bonding and PCAP input.

Display size: 19–27″

Brightness: 2,000–3,000 nits

Contrast: 2,000:1+ with full optical bonding

Enclosure: IP66, IK10 front bezel, ventilated or forced-air cooling with thermostatic control

Certifications: CE / EMC, optional EN50155 for rail projects

Touch: PCAP or PCT with vandal glass and multi-touch

Typical use: Transit hubs, parking terminals.

Display size: 32–55″ (landscape) or portrait configurations for wayfinding/ticket walls

Brightness: 3,000–5,000 nits for direct sun exposed façades

Contrast: Optical bonding + anti-reflective treatment

Power: AC mains with UPS/backup for payment continuity

Cooling: Active cooling with dust filters; consider lower brightness with hooding for extreme temperatures to extend lifetime.

Typical use: Major outdoor station entrances, stadium entry points.

When you approach European transit agencies, city councils, parking operators and integrators, they will look for specific standards and evidence of testing. Below are the most common standards and why they matter for ticket kiosks.

EN 50155 — Railway electronic equipment reliability and environmental requirements. Very relevant for kiosk hardware that is attached to rolling stock or procured under railway-grade RFPs. Suppliers often cite EN50155 compliance for monitors / panel PCs used in railway environments.

EN 50121-3-2, EN 50121 — EMC for railway installations (relevant for deployed station electronics).

IEC 60529 (IP code) — Ingress protection (IP ratings, e.g., IP65/IP66 front). Buyers will require specific IP ratings depending on placement.

IK10 — Impact resistance for front glass/bezel (vandalism protection).

MIL-STD-810 (selected tests) — Commonly used as a benchmark for vibration, shock, humidity and thermal cycling testing (even when procurement is civilian). Many display vendors publish MIL-STD-810 test results to demonstrate ruggedness.

Nits (candela/m²) — Standard luminance metric; specify both peak and sustained brightness (sustained is the typical output the display can deliver continuously). Many suppliers specify a brightness range (e.g., 500–5,000 nits) to indicate variants and dimming capabilities.

Contrast ratio & perceived contrast — Important because high brightness alone does not guarantee legibility; optical bonding + AR coatings improve perceived contrast substantially.

CE marking — Essential for sale in EU markets.

RoHS / REACH compliance — Often required for public procurement within Europe.

EMC test reports (EN 55032/55035 or local variants) — Public agencies require EMC compliance to avoid interference with signalling or ticketing systems.

Distributors win bids by presenting concrete, lab-grade evidence. Below are recommended test categories and example pass levels you should collect and present on datasheets or tender submissions.

Sustained brightness: measured at ambient temperature and after continuous operation (e.g., 1,000 nits sustained over 24 hours with ≤10% drift).

Contrast retention under direct sun: Perceptual tests or photometric measurements comparing contrast ratio with and without optical bonding. Optical bonding often reduces reflections and can increase perceived contrast by a large factor (industry reports and optical bonding vendors report improvements in perceived readability and decrease in internal reflections).

Operating range: −20°C to +60°C (typical for many outdoor ticket kiosks in temperate Europe); for extremes, provide options rated to −40°C/+70°C for high-latitude or alpine deployments. EN50155 requires qualification for temperature classes in rolling stock.

Storage range: −40°C to +85°C.

Thermal cycling: 100+ cycles between min and max operational temperatures to simulate seasonal transitions.

Damp heat steady state / cyclic: e.g., 40°C at 93% RH for 48–96 hours without corrosion or functional degradation. Many transit environments (coastal or underground) produce high humidity; validate conformant protective coatings and conformal coating on PCBs where needed.

Random vibration tests: e.g., 5–500 Hz per MIL-STD-810 or EN standards for rail/road mounted cabinets. Demonstrate no pixel failures and no mechanical failures.

IP ratings: front panel IP65 / IP66 recommended (front face). Provide real test reports demonstrating ingress protection under pressurized water (IPx6) and dust ingress (IP6x).

IK impact: IK08 minimum; IK10 preferred for high-risk locations. Provide impact energy levels and number of strikes tolerated.

Backlight lifetime: specify L70 (time to 70% initial brightness) at typical operating temperature. High-brightness LED backlights often have L70 values of 30,000–50,000 hours depending on thermal management. Provide measured lifetimes at typical kiosk operating temperatures.

This section is for technical buyers and integrators — it explains the main engineering building blocks.

Raising luminance requires more LED current and therefore more heat. Key engineering practices:

Use segmented LED arrays with pulse width modulation and ambient sensors to scale brightness on demand.

Design robust thermal paths (metal chassis, heatsinks, thermal pads) to remove heat from LEDs and drivers so brightness is sustainable without premature luminance decline.

Provide temperature-based derating curves so integrators can forecast brightness vs. lifetime tradeoffs.

Optical bonding laminates the cover glass directly to the LCD using a clear adhesive (silicone or epoxy). Benefits:

Eliminates the air gap that causes internal reflections. This reduces glare and increases contrast and viewing angle. Industry sources and suppliers show substantial improvements in perceived readability after bonding.

Improves mechanical strength and moisture resistance (adhesive seals edges).

Improves shock/vibration tolerance (adhesive distributes forces and reduces delamination risk).

AR coatings reduce specular reflection (mirror-like glare), while AG diffuses surface reflections. Many outdoor kiosks use a combination (hard coating + AR multilayer) to balance scratch resistance and low reflectance.

Specialized polarizers and compensated viewing polarizer stacks can be used to optimize contrast under polarized sunlight. Military and specialized displays use NVIS-compatible polarizers as needed; civilian ticketing kiosks typically use standard high-contrast stacks.

Capacitive touch (PCAP) with water rejection algorithms and glove detection is preferable. Resistive touch may work for low cost but suffers in clarity and multi-touch. Additives like hydrophobic coatings or proximity sensors can improve performance when wet.

Distributors should position high-brightness kiosks not as premium cost centers but as investments that lower downtime, reduce maintenance visits, and increase transaction throughput. Key TCO levers:

Energy consumption vs. uptime: high brightness increases power consumption — offer models with ambient dimming and efficient LED drivers.

Serviceability: modular designs (field-replaceable display module) shorten mean time to repair (MTTR).

Warranty & spares: provide 3–5 year warranty options and guaranteed spare availability for at least 7–10 years for transit contracts.

Offer bundle deals: display + enclosure + payment terminal + installation support. This simplifies procurement for municipalities and integrators.

Consider offering "display as a service" or managed maintenance contracts for recurring revenue.

For payment kiosks, ensure PCI-DSS considerations for the payment terminal and physical tamper-resistance of the display housing. Provide documentation for CE/EMC, and local recycling/disposal compliance (WEEE) in EU countries.

Europe’s digital signage market was estimated at USD 7.98 billion in 2024 with projected growth through the decade, driven by retail, transit modernization and smart city projects — showing a strong addressable market for outdoor kiosk displays.

Industry guidelines and vendor whitepapers consistently show that displays of ~1,000 nits are the practical lower bound for "sunlight readable" performance; many transit and outdoor kiosk applications prefer 1,500–5,000 nits, combined with optical bonding for best perceived contrast.

EN50155 and railway-grade certifications remain decisive in railway procurements; for station and platform equipment, EN standards for EMC and environmental tolerance should be addressed in tender documents.

(These five citations are the most load-bearing facts used above: market size/growth, nits guideline, optical bonding benefits, IP/ingress requirements, and EN50155 relevance.)

Below are example case styles and short testimonials you can adapt for bids. When you use real customer quotes, make sure to request permission and include project specifics.

Challenge: Platform ticket machines were unreadable on sunny platforms and frequently returned for panel replacements due to moisture ingress.

Solution: Replace indoor-spec panels with 2,500-nits, optically-bonded 19″ displays in IP66 housings with IK10 front bezels and ambient sensors.

Result: 45% reduction in reported display issues; average transaction time down 12% due to faster UI acceptance; zero returns in 18 months.

Customer quote (example): “Since switching to the high-brightness bonded displays, our field maintenance calls decreased sharply — a clear win for passengers and operations.” — Transit Systems Integrator.

Challenge: Seasonal glare on payment terminals resulted in abandoned transactions.

Solution: 15″ ticket displays with 1,500 nits, AR coated glass, and automatic contrast scaling.

Result: 22% uplift in successful payments during high-sun months; positive customer feedback on readability.

(Use anonymized or permissioned testimonials. If you have in-house test logs, attach them as appendices when prospect requests RFP compliance.)

Lead with measured test data: sustained brightness, L70 lifetime, IP/IK reports, vibration/shock tests, EMC reports, and temperature profiles.

Offer project templates: e.g., “Platform Kiosk Kit — includes 19″ 2,500-nit bonded display, IP66 bezel, integrated heater, and PCAP + payment mount” with BOM and priced options.

Provide life-cycle warranties and optional on-site commissioning. Show cost comparison that accounts for fewer field calls and longer display lifetimes.

Offer pilot deployment at discounted rate for early adopter transit agencies — a low friction path to larger rollouts.

Include in tender responses:

Photometric test data and sustained brightness curves.

IP/IK test certificates.

EMC / CE / RoHS documentation.

Environmental test protocols (vibration, thermal cycling results).

Service level agreement (SLA), spares provisioning, and Uptime guarantees.

Q: What brightness is "sunlight readable"?

A: Practical minimum is ~1,000 nits for shaded outdoor or late-sun conditions; 1,500–5,000 nits for direct sun-facing kiosks depending on optical treatments. Always present sustained brightness and thermal derating curves.

Q: Do optical bonding and AR coatings replace high brightness?

A: No — they complement each other. Bonding and AR reduce reflections and improve perceived contrast; high luminance combats ambient washout. Best designs combine both.

Q: What IP rating should we demand for front face?

A: IP65 is the minimum for general outdoor protection; IP66 is better for high-pressure water exposure. For kiosks in harsh coastal or street cleaning environments, IP66 front and IP54 rear is typical.

Q: When is EN50155 required?

A: EN50155 is required when the equipment is procured as part of rolling stock or installed on vehicles. Many rail operators also favor railway-grade components for station equipment; clarify with the procuring authority.

When approaching European buyers, supply a single PDF or webpage containing:

One-page spec sheet (brightness, contrast, L70, IP/IK, touch type, size options).

Photometric graphs (light vs. distance, brightness vs. temperature).

Environmental test summary (vibration, shock, humidity, thermal cycling).

Certifications & test reports (CE, EMC test reports, IP/IK test certificates, EN50155 if applicable).

Case studies (2–3 short project briefs with customer quotes).

Warranty, spare parts, and service offerings.

Sample tender language (boilerplate spec text).

(Use this template in RFP responses and datasheets.)

Display module — Outdoor Sunlight Readable (example)

Model family: RS-HBxx (example)

Sizes: 12.1", 15", 19", 22", 27", 32", 43", 55"

Display type: a-Si TFT LCD with LED backlight

Brightness (typical/sustained): 2,500 nits / 2,200 nits sustained at 25°C

Contrast ratio: 2,000:1 (native); perceived contrast improved with optical bonding

Optical bonding: yes (silicone/epoxy)

Surface treatment: AR + AG + Hard coating (≥3H)

Touch: PCAP multi-touch (glove mode, water rejection)

Front ingress: IP66; rear enclosure: IP54 (optional fully sealed IP66)

Impact rating: IK10 front bezel

Operating temp: −20°C to +60°C (option: −40°C to +70°C)

Storage temp: −40°C to +85°C

Backlight lifetime (L70): ≥50,000 hours at 25°C (specify derating)

Certifications: CE, RoHS, EMC test reports; EN50155 option available on request

Warranty: 3 years standard, optional 5-year extended with spares program

Europe is actively modernizing transit, parking and mobility infrastructure. The shift toward contactless, self-service and smart city amenities drives sustained demand for reliable, readable outdoor displays in ticket and payment kiosks. Distributors who can combine technically validated, standards-backed hardware with service, spares and project-level procurement support will be positioned to capture long multi-site rollouts.

To win large tenders, lead with measured performance data (photometric curves, IP/IK and vibration test reports), modular supply chain assurances (spares, field replaceable modules), and financing or pilot programs that reduce procurement friction.

If you'd like, I can:

Convert this article into a formatted tender-ready datasheet and one-page executive summary for European buyers.

Draft a sample outreach email pitch and landing-page copy targeted at transit integrators and municipal procurement teams.

(Reply which deliverable you want next and I’ll produce it right away — no waiting.)

Europe digital signage market overview — Grand View Research (2024 market estimate and growth projections).

EN50155 overview & its relevance to railway electronics — Assured Systems / industry commentary.

Sunlight readable display fundamentals and typical nits guidelines — TRU-Vu, Abraxsys, Riverdi technical blogs.

Optical bonding & benefits (readability, durability) — Touch International whitepaper and Things-Embedded technical guide.

IP and IK ingress/impact guidance — Integra Enclosures technical references.

Examples of railway-grade monitor offerings and EN50155 compliant monitors — Relec Electronics / vendor pages.

Ask a quote for the latest price and one of our team members will respond as soon as possible.